10 Common Causes of Print Misregistration in Flexographic Printing

We've all had that moment when we're painting, tracing, or gluing something and in our intense concentration, our hand slips, marring our precious work.

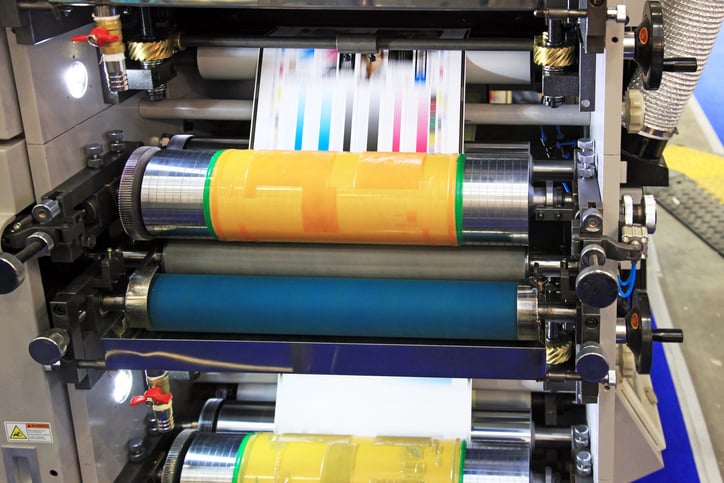

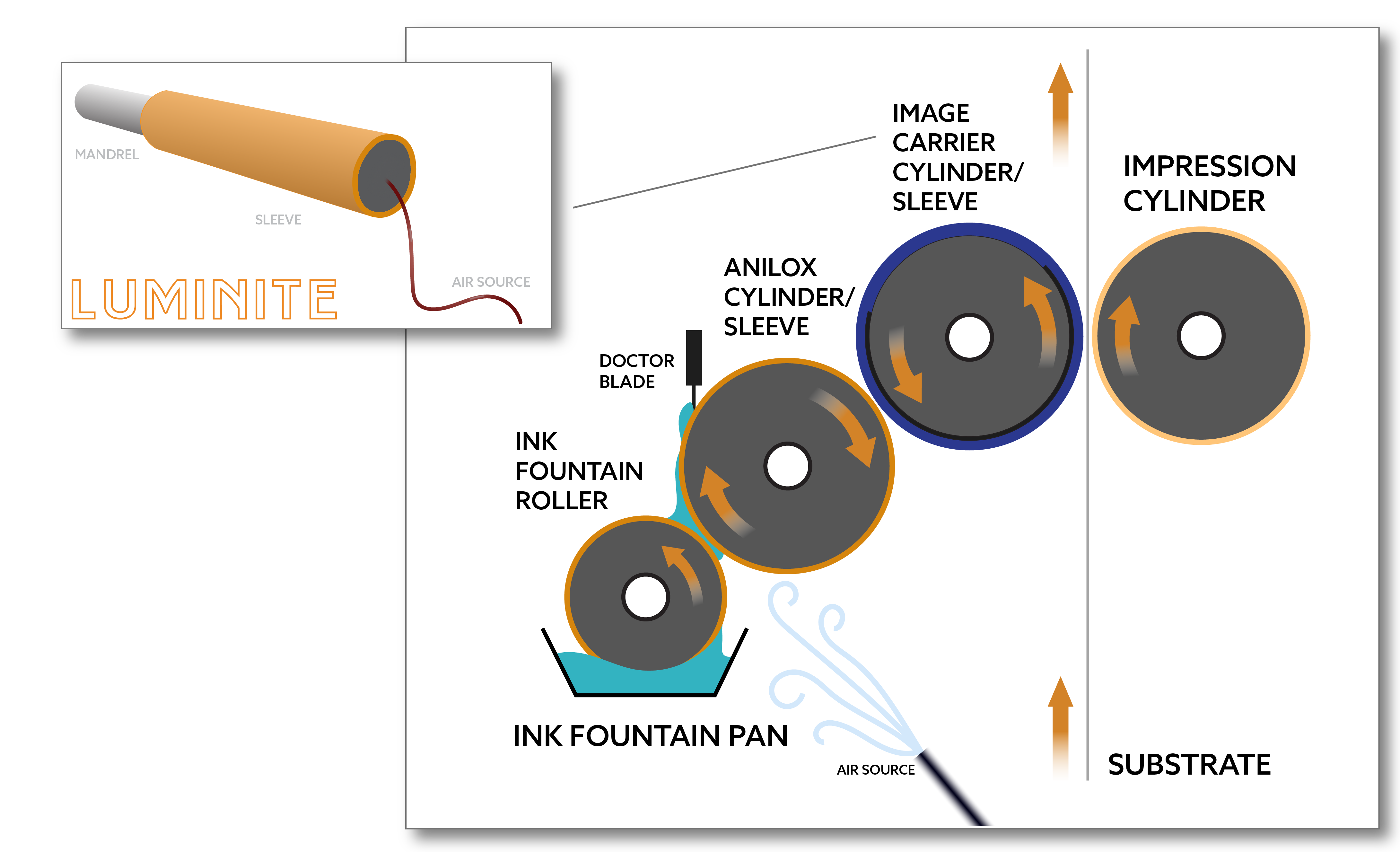

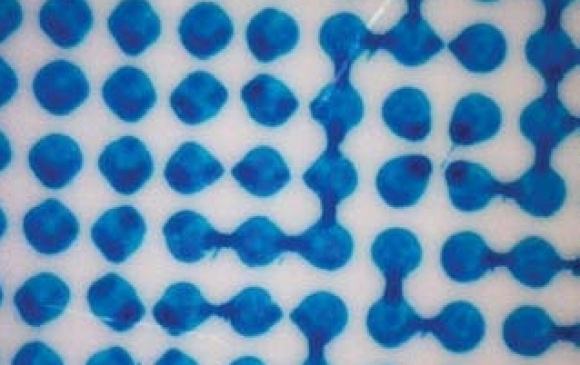

That's what print misregistration is like. To get the best possible print, the alignment of...