Share this

Flexographic Printing Press Parts: What’s a Mandrel?

by Luminite on Sep 13, 2023 10:59:41 AM

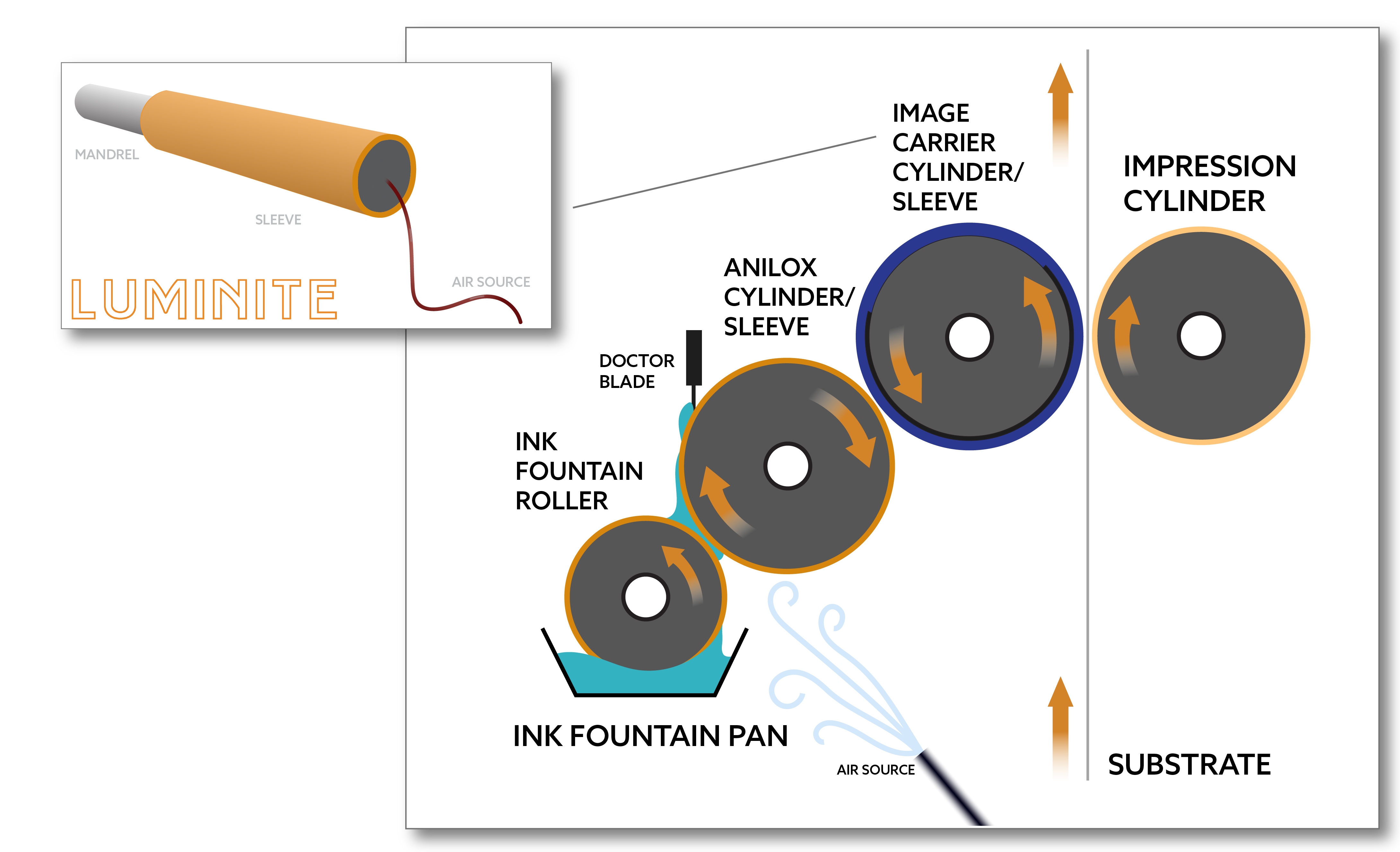

There are a variety of press types that can be utilized for flexographic printing. However, in order to provide a high-quality print, each printing machine must include certain elements. For the presses that utilize a print sleeve, the following is the typical Printing Press Sleeve setup:

- Mandrel

- Sleeve

- Air Source

The process to secure the sleeve to the mandrel requires 80 lbs. of air pressure, which is used to slightly swell the fiberglass and allow the sleeve to slide onto the mandrel easily.

The air source connects to the mandrel, and the air flows through holes at the end of the mandrel. Once the sleeve is in place, the air is removed. Without air, the sleeve adheres to the mandrel and can’t be moved. This provides a more detailed and replicable print.

[Maintenance Tip: The mandrel has to be cleaned with alcohol prior to placing the sleeve. Anything the thickness of a human hair can stop the sleeve from sliding on.]

Did You Know?

- A mandrel can last 20 years with the proper maintenance. Therefore, it is cost-effective to adhere to a strict cleaning process.

A Little About Load-n-Lok

Luminite’s patented “Air Sleeve” system provides flexibility. With the Load-n-Lok system, sleeves and mandrels can be different lengths. The air source is attached to the sleeve, rather than the mandrel.

Benefits of this system include:

- Faster printing speeds

- The ability to use multiple sleeves on the same mandrel

- The ability to use one sleeve on multiple presses with the same BCD

- Flexibility to serve multiple customers at once with multiple sleeves on the mandrel.

Note: With the Load-n-Lok, the air is applied to the sleeve with a special tool that attaches to the sleeve itself. Load-n-Lok sleeves are highly recommended for narrow web printers.

Flexographic Printing Press Parts: Next Steps

The mandrel and sleeve are two necessary flexographic printing press parts. Understanding their place in the printing process can better facilitate flexographic printing optimization.

Where to Go From Here? Luminite Resources:

Flexography Step-by-Step: How Flexographic Printing Works

Printing Press Breakdowns:

Breaking Down An In-Line Flexo Printing Machine

Central Impression Printing Press: A Breakdown

Stack Press Breakdown: Parts and Processes

Identify Printing Defects:

Diagnostic Chart & Troubleshooting Guide for Flexo Printing Defects

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

No Comments Yet

Let us know what you think