Share this

Digital vs. Flexo Printing: Pros and Cons

by Luminite on Oct 5, 2023 10:07:35 AM

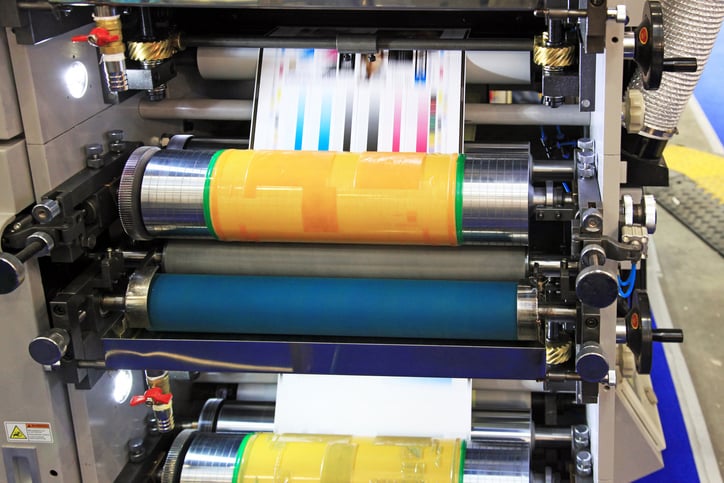

Flexographic printing, which is a type of relief printing, uses a laser-engraved sleeve to transfer ink onto paper. The presses run at a high speed, making them ideal for longer print runs. Flexo printing has been a relied-upon technique for many years, providing quality prints that are cost-effective and clear on a variety of substrates.

Over the last two decades, digital printing has become increasingly popular. Digital printing technology offers higher-resolution prints with greater color fidelity than traditional flexo methods. Digital printers also provide new capabilities such as variable data printing that allow for more customization options for businesses and individuals alike. However, when it comes to longer print runs, flexo provides the best speed and reliability.

When deciding between Digital and Flexo Printing, it is essential to consider:

- Your production timeline

- Color range for the image

- The type of material you need to be printed

Understanding Flexo Printing

Flexo printing involves the creation of a raised design on an image carrier - typically a sleeve, cylinder, or plate that can be made of polymer or elastomer. The anilox roller takes ink from the inkwell and transfers it to the image carrier, which then applies the image to the substrate.

Substrates that utilize this method can be paper, flexible plastics, and other non-porous materials. This can range from film and labels to foil or other packaging materials.

Flexo printing is best used when it comes to large volumes of production over several days or weeks as it tends to be more economical in that sense than digital printing. This method is also more efficient in terms of speed and time spent from setup to completion of a print run.

| Pros of Flexo Printing | Cons of Flexo Printing |

|

|

Understanding Digital Printing

Digital printing is a process that involves the use of a digital image and specialized printers to transfer the image onto a substrate. The digital image is created on a computer with high precision and accuracy and then printed directly onto the substrate. Digital printing technology eliminates the need for plates or film used in traditional offset printing, making it faster and more efficient than other forms of printing.

The digital printers output images directly from a computer, scanning each pixel of the image as it prints. This allows for great detail, clarity, and accuracy in producing complex images on substrates such as paper, vinyl, fabric, film, foil, synthetic papers, and various boards. Digital printing also enables variable data printing – which allows different pieces of text or artwork to be printed in one pass without stopping or changing plates.

The advancements in digital printing have improved turnaround times and offered increased customization options to customers. With better quality prints at faster speeds, digital is a preferred method of choice for those looking for quick and effective commercial or personal printing solutions - in smaller batches.

Digital printing offers a higher degree of detail than flexo printing, resulting in better image quality and accuracy.

| Pros of Digital Printing | Cons of Digital Printing |

|

|

Digital vs. Flexo Printing | Summing Up

Digital offers speedier turnaround times and better detail while Flexo provides larger volume print runs at an economical cost. As for flexibility, both methods offer various options for different paper types and sizes but Digital is often more versatile when it comes to small orders on different substrates, while Flexo is the preferred method if you are relying on longer print runs, especially for an extended amount of time.

Need Answers to Your Flexo Printing Questions?

The Luminite staff has been helping printers address defects in their Flexo Print runs for years. If you have issues with your quality, take a look at this resource:

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (1)