Ultimate Guide to Corrugated Packaging Printing With Flexo

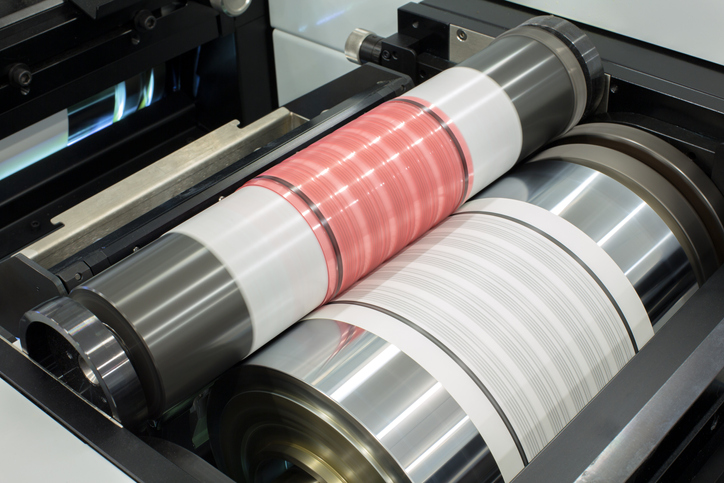

Corrugated packaging and printing have come a long way in recent years. Although durable during shipping, corrugated substrates are spongy and can be easily crushed during an indelicate printing process.

As a result, businesses once had to settle...