Share this

Anilox Volume Guide (+ FREE Print Out Chart!)

by Luminite on Apr 11, 2022 8:34:00 AM

Anilox volume refers to the carrying capacity of an anilox cell, or the amount of ink held in each cell, during Flexographic Printing.

Anilox volume refers to the carrying capacity of an anilox cell, or the amount of ink held in each cell, during Flexographic Printing.

It is one of the many factors that determine the amount of ink that is transferred to the print material and therefore has to be accurately controlled and measured.

Anilox Volume 101: The Basics

When understanding the importance of cell volume considerations in your flexo printing process, it is first important to have a comprehensive knowledge of how the anilox functions

The function of the anilox is to measure and control the volume of ink delivered to the image carrier.

The amount, or volume, of ink that is transferred to the image carrier is dependent on the size and number of engraved cells that are on the anilox, as well as the ink that is used.

The anilox cell volume determines both the amount of ink the image carrier receives, as well as the density of the resulting ink.

Anilox Volume Measurements

Cell carrying capacity is measured in Billions of Cubic Microns (BCMs). Microns are very small units of measurement; with human hair actually being 70 microns thick in diameter. Cell volume is expressed in billion cubic microns per square inch, or BCM/in².

Some of the conventional anilox cell measuring tactics include microscopic measurement and liquid volume measurement.

Ink Considerations

As the FTA notes, “It is important to understand that anilox volume is the single most important factor in determining ink film thickness.”

It is often beneficial to print with the thinnest ink film possible, and this has to correlate with your anilox volume for the best results in your specific type of operations. High anilox volumes give high solid ink density and more color, while low anilox volumes transfer less ink to the image carrier, resulting in sharper graphics.

When you try to print with high anilox volumes, it will be difficult for you to achieve optimum flexographic printing. Thin films of wet ink, on the other hand, make it easy to control the printing process. They enable you to reduce dot gain, achieve smaller dots, sharper edges, and ultimately cleaner printing.

For more information on how to optimize the printing process, download the ebook below!

Line Screen Considerations

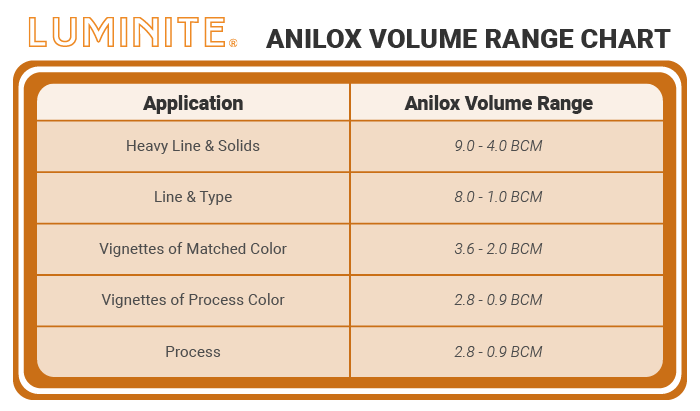

One of the most important factors to take into account when printing is the anilox volume and line screen interaction. A printer must be able to get the right combination of these two factors for their anilox roll to fulfill their specific printing job’s needs.

A banded anilox is one tool that print operators can use to test and determine the correct set-up to deliver adequate color strength and still print the thinnest ink film possible.

With the modern manufacture of high-strength inks and small carrying capacity cells, printing operators can now use higher line screen anilox rolls to produce higher line screen graphics (such as using an anilox volume of 1.0 BCMs for a 1,000 anilox line screen).

All in all, in addition to learning about anilox volume, it’s prudent to have some understanding of line screen and anilox rolls.

Note: A good rule of thumb for determining line count on an anilox, is to make sure the line count is minimum of 6 times that of the line screen in your image carrier design. However, this is not a “one size fits all rule” and it is always best to ask your anilox provider to find out what is best for your print.

Is It Time to Replace Your Anilox?

Anilox cell volume changes over time because of factors such as dirt or wearing out of anilox rolls. It’s important to measure the volume of your anilox periodically to monitor for wear and tear and ink plugging that can affect performance.

Poor print quality and other print defects may be a result of your anilox simply needing to be cleaned or resurfaced. If the cells are dirty or blocked, color, and cell volume may be restored with a thorough cleaning.

But if their wear is permanent, they need to be resurfaced or replaced to avoid lower quality printing.

(Editor's Note: This blog post was originally published Sep 14, 2018, and was updated in May 2023 to reflect updated information, and an improved chart.)

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (4)