Share this

Surface Tension Test Ink Makes Measuring Wettability Easy

by Luminite on Feb 16, 2022 10:30:00 AM

Surface tension is one of two key factors in proper substrate wetting (the other being surface energy). Tension is what causes liquids moving to form into a spherical shape, as if they are surround by an elastic membrane under tension. The molecules want to stick to each other instead of breaking apart in the air. It can also keep small particles from sinking into liquids.

In flexo printing, surface tension has implications regarding ink coating properly on the substrate. Fortunately, surface tension can be measured using surface tension test ink.

This makes sure the surface is ready for printing and provides quality assurance controls during the printing process.

Here is everything you need to know about surface tension test ink, including its limitations:

How Does Surface Tension Test Ink Work?

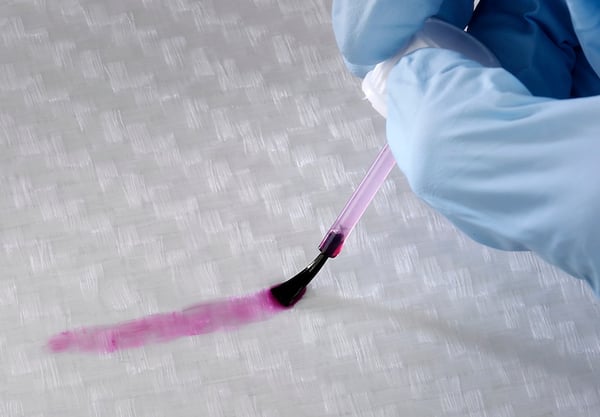

(Image courtesy PlasmaTreat)

(Image courtesy PlasmaTreat)

Still not sure how to measure surface tension? For starters, since the objective of a flexo surface tension test is to determine surface wettability, know that test inks come in several surface tensions. That's a good thing, because surface wetting can be quite a challenge.

After pretreatment, the tester uses a brush to quickly apply a high-tension test ink to the surface. If the brush stroke edges remain stable for 2 seconds, that surface is considered to be wettable.

If the ink appears more in drop form than even strokes, the tester moves on to the next lower level of test ink until the tension of the surface is at least equal to that of the test ink.

Which Materials Are Used as Surface Tension Test Ink?

Depending on the surface being checked, several types of ink may be used for a wetting tension test.

- Ethanol Test Inks: These are suitable for most common surfaces.

- Formamide Test Inks: These work on warmer surfaces but are not appropriate for PVC. Extra care is required, as these inks are toxic and require a longer reading time to discern results properly.

- Methanol Test Inks: Again, these will work with most common surfaces, but these inks are also toxic, so great care is a must.

As a press operator, you may not want to invest in new test inks -- and you might not have to! To make it easier, you could follow the same procedure as noted above, but use your own press-ready ink.

The Importance of Surface Tension in Flexographic Printing

The top priority in printing is to make sure the ink wets out on the substrate evenly. Due to the increased use of water-based inks and different types of substrate materials, more flexographic printers use this simple surface tension measurement so they can adjust the treatment process accordingly.

Failure to incorporate these techniques can result in:

- Lack of adhesive properties

- Poor print quality

- Production interruptions

- Dissatisfied clients

Possible Limitations of Ink Testing

These measurements are relative values, and there may only be slightly perceptible differences from one surface tension to the next.

The test only measures the surface tension/wettability of a specific sample of the substrate in a given environment at one certain point in time. The test materials must be exactly the same as the materials that'll be used in the printing process. As the testing continues, the nature of the substrate itself might change in relation to environmental factors.

Any delay between surface wettability testing and printing could result in different outcomes. Industry experience and a critical thought process are crucial to successfully using ink tests.

No Surface Tension Measurement Is 100% Failproof

While no surface tension ink test is 100% failproof, sending your materials for out-of-house testing can yield more accurate results. A flexographic products supplier may already have the surface tension measurement methods and equipment in place to get you through testing smoothly.

If you’re experiencing printing defects linked to surface tension, give us a call. A member of our technical support team will walk you through your options.

(Editor's note: This article was originally published in July 2018 and was recently updated.)

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (3)