Elastomer Sleeves vs Photopolymer Plates for Flexo Printing

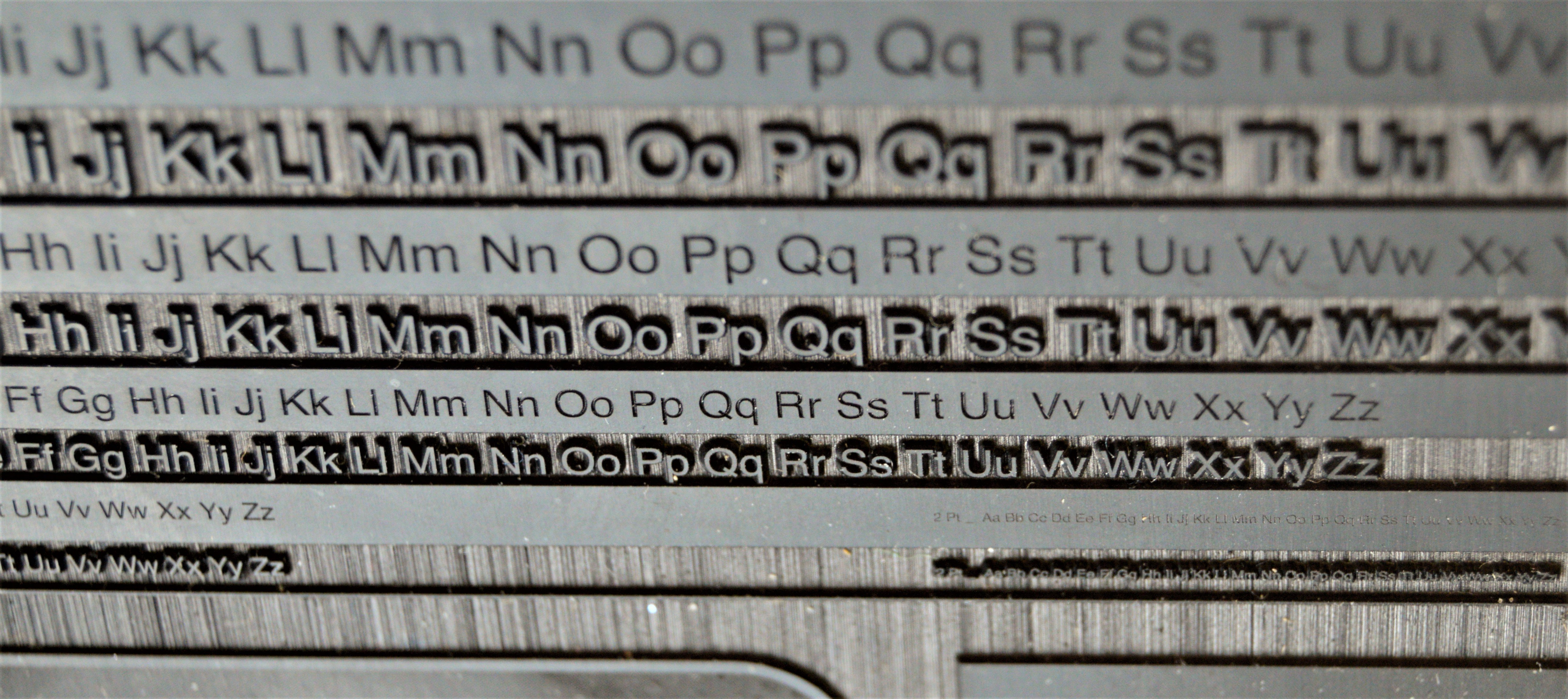

When thinking about the various components involved in making a final flexo printed product, one of the most important elements to thoroughly consider is your image carrier selection.

After all, when your image carrier is not optimized for your...