Flexographic Printing Press Parts: What’s a Mandrel?

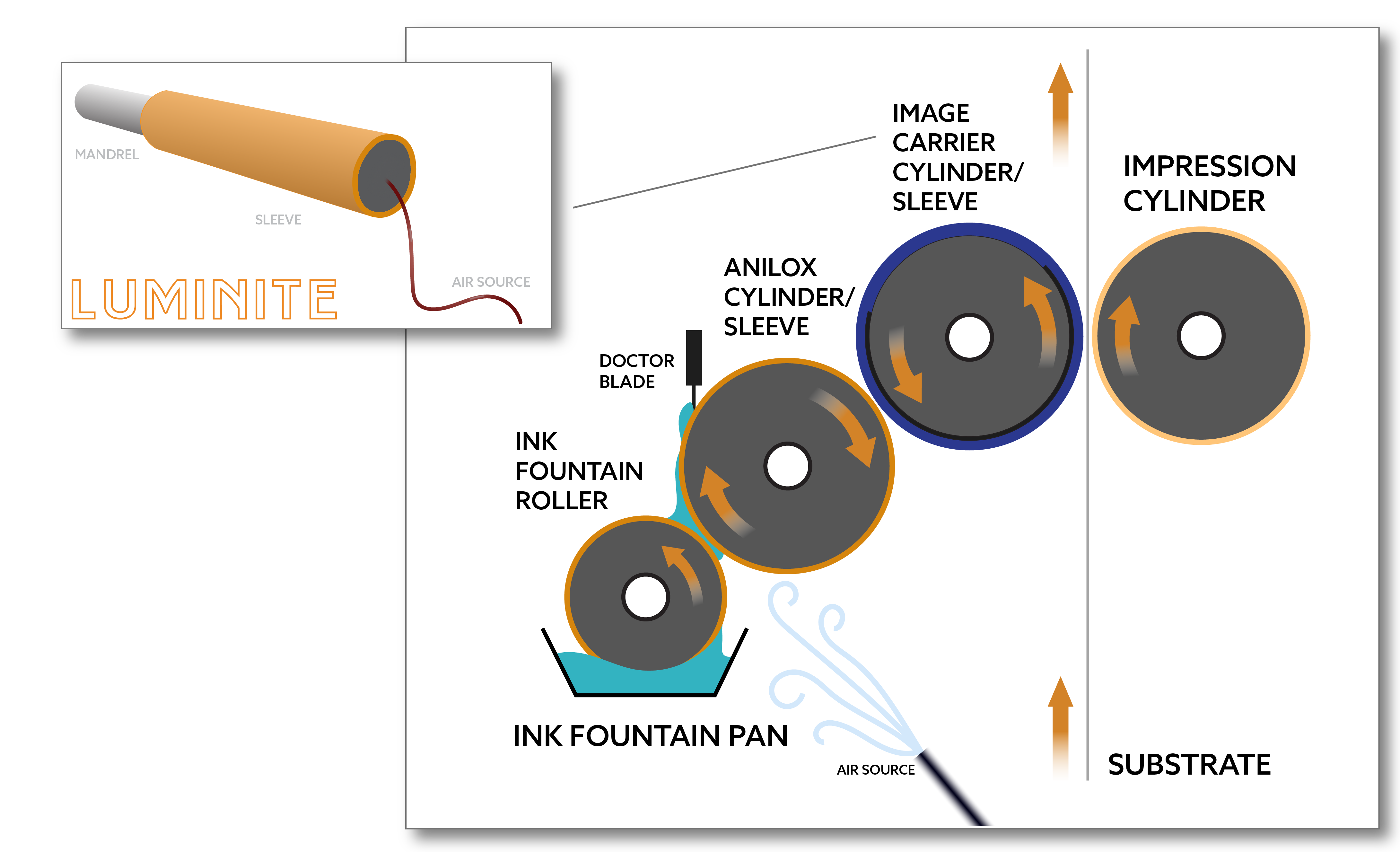

There are a variety of press types that can be utilized for flexographic printing. However, in order to provide a high-quality print, each printing machine must include certain elements. For the presses that utilize a print sleeve, the following is...