Flexo Printing Defects: How to Clean Up Your Dirty Prints

Clean up your act! OK, so we know dirty print is not all your fault.

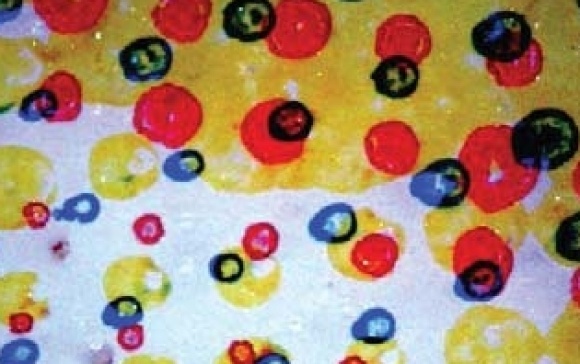

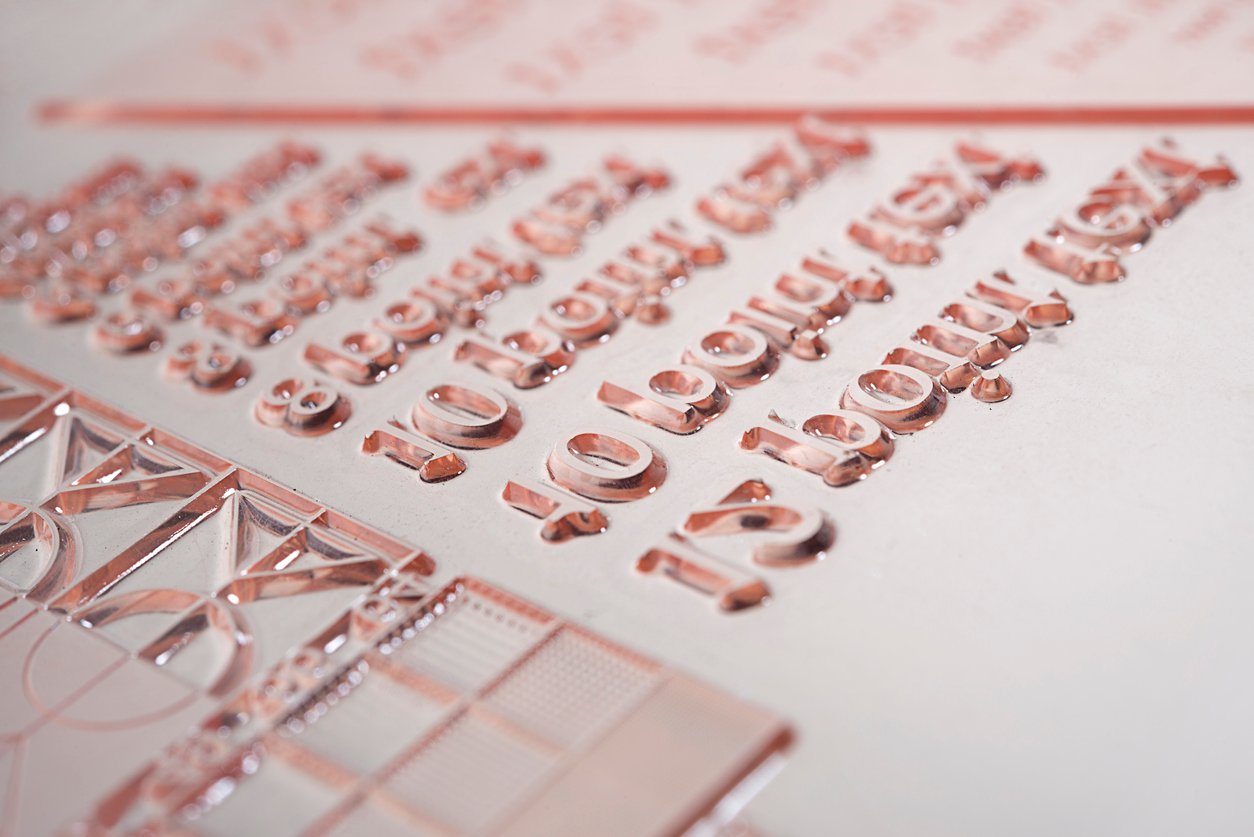

Among other common flexo printing defects, dirty print is particularly confounding. It can stem from contamination, ink consistency, plate/sleeve issues, pressroom atmosphere, and...