Flexo vs Litho Printing: A Comparison for Modern Print Solutions

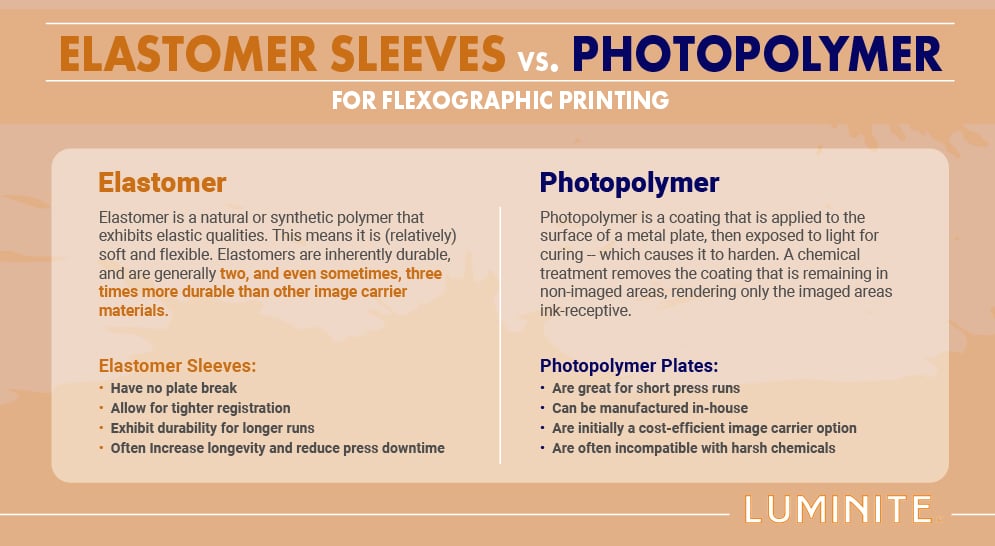

Commercial printing is changing rapidly, and the processes that produce the consumer goods we all see daily are growing and changing as quickly as we are. Among the various printing methods available, flexographic (flexo) and lithographic (litho)...

.png)