Share this

Flexo vs Litho Printing: A Comparison for Modern Print Solutions

by Luminite on May 4, 2023 9:32:05 AM

Commercial printing is changing rapidly, and the processes that produce the consumer goods we all see daily are growing and changing as quickly as we are. Among the various printing methods available, flexographic (flexo) and lithographic (litho) printing have long been two of the most popular options.

As you consider which technique best fits your needs, understanding the differences between these methods can make all the difference. Below, we delve into flexo vs litho printing, exploring their strengths, weaknesses, and ideal applications.

In case you missed it, we’ve also spent some time comparing flexo with some other popular printing methods:

Flexo Printing vs Litho Printing: The Similarities

Despite being distinct printing methods, flexo and litho printing do share some similarities, such as:

- Planographic printing: Flexo and litho printing belong to the same family of printing techniques called planographic printing, which involves printing from a flat surface. This contrasts relief or intaglio printing, where the printing surface is either raised or recessed.

- Plates: Both methods require plates to transfer the ink onto the substrate. Flexo printing uses flexible photopolymer plates, while litho printing employs metal or aluminum plates.

- CMYK and Spot Color Printing: Flexo and litho printing are both capable of producing high-quality prints using the CMYK (cyan, magenta, yellow, and black) color model, as well as spot colors for more precise color matching.

- Substrates: Both methods can print on various materials, including paper, cardboard, plastic, and metal.

- Commercial Scale Production: Both flexo and litho printing are widely used in commercial print environments due to their ability to produce large volumes of high-quality prints in a relatively short time.

While lithographic printing might dominate some markets, flexo printing has increasingly gained popularity since the 1970s with the introduction of direct laser engraving.

Flexo Printing: The Basics

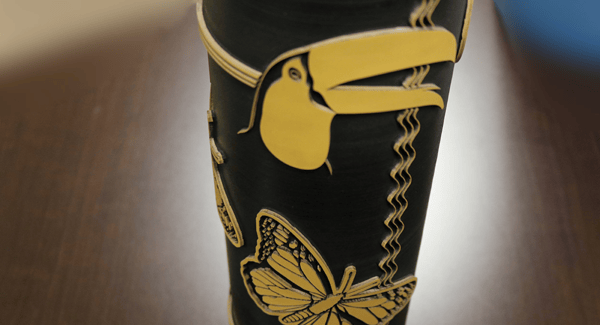

The flexographic printing process typically utilizes an elastomer or polymer image carrier such as sleeves, cylinders, and plates. The image carrier is engraved or imaged to create the design for the final desired product. Flexo ink is transferred from the ink pan via an anilox roll onto the image carrier, then printed onto the substrate.

Flexo printing is most commonly associated with uses in flexible packaging and labels, utilizing a variety of substrates including film, paper, foil, and non-woven.

Litho Printing: The Basics

Litho printing is an offset process that uses a printing plate. The ink is first applied onto the printing plate and then transferred to a rubber blanket through multiple ink rolls, and finally applied to the substrate from the blanket.

This means the image is not printed directly onto the substrate from the plate.

Flexo vs. Litho: Key Differences

The main areas to compare flexo printing and lithographic printing are:

- Cost

- Substrates

- Inks

- Image quality

How much this affects your operation largely depends on the types of final prints you're hoping to accomplish.

Cost

When comparing the cost of litho and flexo printing, several factors come into play, including setup costs, plate costs, and ink costs. Here’s a general comparison of these costs for both printing methods:

- Setup Costs: Litho printing typically has higher setup costs than flexo printing. This is because litho printing requires more time and effort to set up the press, register the plates, and achieve the desired color balance.

- Plate Costs: Flexo printing uses flexible photopolymer plates, which are generally less expensive than the metal or aluminum plates used in litho printing.

- Ink Costs: Flexo printing uses a lower ink volume per print, which can contribute to cost savings.

Litho can accommodate foil stamping, spot gloss, embossing, and other embellishments, but these options also come at a higher cost. Additionally, since the only way to print with litho is through an indirect pre-print, this guarantees an additional step in production, thus raising costs.

Both processes can be very cost-effective when printing large runs with basic needs. With proper maintenance and storage, as well as an investment in durable image carrier materials, flexo image carriers can be reused many times before they need to be replaced.

Substrates

Litho is generally limited to printing on smooth, flat surfaces as the image must be pressed onto the substrate. Printing on corrugated substrates requires an additional step in production where the images are first printed onto linerboard, which is then attached to the corrugated substrate.

Flexo can print on porous and non-porous surfaces, making it ideal for various substrates, including coated linerboard and paper.

Inks

Litho printing generally uses oil-based inks, and the printing process usually consists of four process colors, each requiring a dedicated printing station.

Flexo also utilizes one image carrier per color and can use oil-based inks, though it also accommodates printing with a wide variety of other flexographic inks -- including water-based, solvent-based, and UV inks. Curable inks, such as UV, afford faster drying times. Faster drying can lead to faster production runs.

Image Quality

While both processes can produce good print quality, Flexo printing is noted for producing superior prints with fine lines and text detail in a fraction of the time compared to Litho printing.

When deciding between flexo and litho printing, carefully consider factors such as your project’s budget, substrate, and a number of other production requirements. By understanding the capabilities and limitations of each printing method, you can make an informed decision that best suits your project’s unique needs.

Editor's Note: This blog post was originally published in 2018, and was revised to reflect recent information and insight.

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (2)