Share this

Flexo Printing vs Gravure Printing: Pros and Cons

by Luminite on Mar 15, 2023 12:06:00 PM

Commercial printing relies on a variety of technologies to print on different substrates, but two of the more popular techniques are flexographic printing and gravure printing.

This post is designed to take a closer look at the key differences in flexo printing vs. gravure printing. Better understand these two printing technologies will ensure that you use the right process for your application.

(ICYMI: We've also discussed the differences between Flexo Printing and Offset Printing.)

Flexo Printing Vs. Gravure Printing:

The disadvantages and advantages of gravure printing and flexo printing involve several factors:

- Cost and lead time

- Substrates

- Ink

- Environmental considerations

- Quality

For those not familiar with one or the other, here's a quick rundown of the flexo and gravure printing processes:

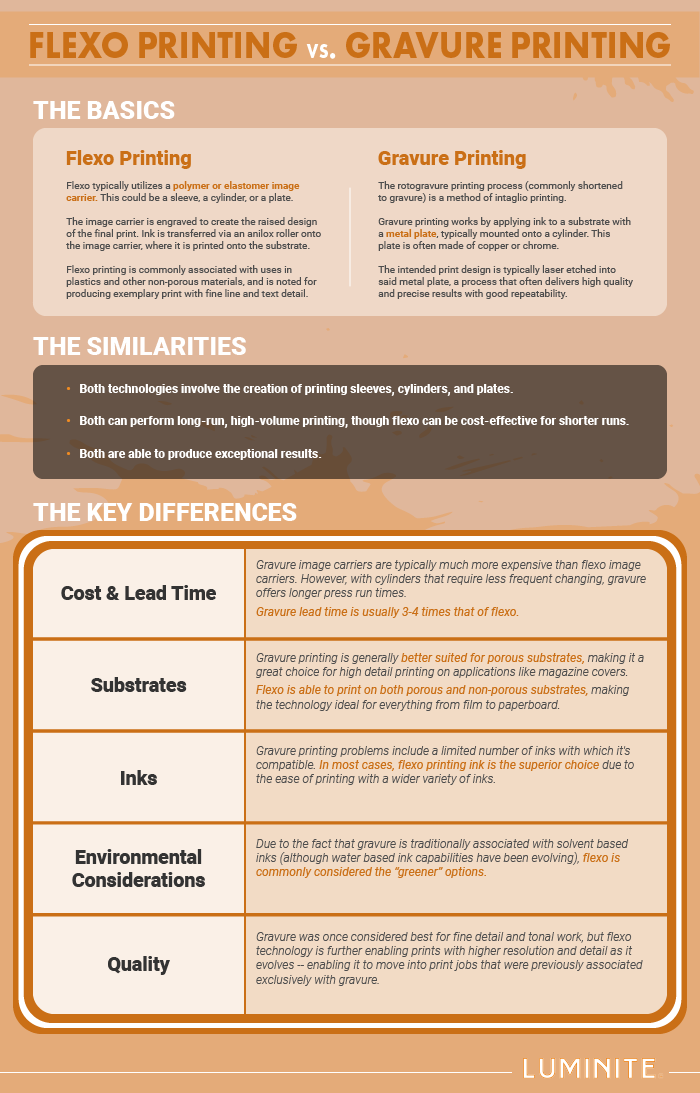

Basics of Flexo Printing

Flexo typically utilizes a polymer or elastomer image carrier. This could be a:

- Sleeve

- Cylinder

- Plate

The image carrier is engraved to create the raised design of the final desired print. Ink is then transferred from the inkwell via an anilox roller onto the image carrier, where it is then printed onto the substrate.

Flexo printing is more commonly associated with uses in flexible plastics and other non-porous materials such as film, labels, foil, and other packaging.

Flexo is noted for producing an exemplary print with fine lines and text detail.

Have questions on Flexographic basics? Check out our new Flexo 101 resource hub below:

Basics of Gravure Printing

The rotogravure printing process (commonly shortened to gravure) is a method of intaglio printing. Gravure printing works by applying ink to a substrate with the use of a metal plate that is typically mounted onto a cylinder. This plate is often made of copper or chrome.

The image or text that is intended for printing is typically laser etched into said metal plate, a process that often delivers high-quality and precise results with good repeatability.

The Similarities

But before we get into the differences, however, let’s take a look at a few key similarities:

- Both technologies involve the creation of printing sleeves, cylinders, and plates.

- Both can perform long-run, high-volume printing, though flexo can be cost-effective for shorter runs.

- Both are able to produce exceptional results.

Flexo Printing vs. Gravure Printing: Key Differences

Now that we’ve gone over the similarities between flexo and gravure, and explained the basic process of each, it’s time to take a look at some of the key differences:

Cost and Lead Time:

Gravure image carriers are typically much more expensive than flexo image carriers, making the number of prints required to break even much higher. Gravure, however, has a longer press run time, as the cylinders do not require as frequent changing as those in the flexo printing process.

Gravure lead time is usually 3-4 times that of flexo in the time it takes to manufacture the image carrier.

Substrates:

One of the limitations of gravure printing is that it is generally better suited for porous substrates. This is one of the reasons that gravure is best suited for high-detail printing on applications such as magazine covers.

That isn’t the case with flexo printing, which is able to print on both porous and non-porous substrates, making the technology ideal for everything from film to paperboard. In you're specifically measuring flexo vs. gravure in packaging printing, you'll usually find that flexo wins.

Inks:

Another key differentiator in flexo vs. gravure is the range of inks flexo is able to print with. Gravure printing problems include a limited number of inks with which it's compatible. In most cases, flexo printing ink is the superior choice due to the ease of printing with a wider variety of inks.

Gravure requires much more ink per print, which can drive up the cost of printing.

Environmental Considerations:

Due to the fact that gravure is traditionally associated with solvent based inks (although water based ink capabilities have been evolving), flexo is commonly considered the “greener” options.

There are generally more flexo printing solutions for VOC (volatile organic compound) problems, and the press operations are associated with more environmentally friendly practices.

Quality:

Gravure was once considered best for fine detail and tonal work, but flexo technology is further enabling prints with higher resolution and detail as it evolves -- enabling it to move into print jobs that were previously associated exclusively with gravure.

Consider the other pros and cons of gravure printing and weigh them against the slight (if any) difference in end quality you'll get with flexo.

Flexo or Gravure: The Final Decision

As you can see, there are many differences between flexo and gravure printing.

Which process is right for you? It largely depends on the job, substrate, and a variety of other factors of the job you're printing. Don't substitute one printing process for the other without thinking it through with your internal team and an external printing expert.

(Editor's note: This blog post was originally published in August 2018 and was updated in March 2023 to reflect current and up-to-date information.)

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (13)