Share this

How Load-N-Lok Revolutionized Flexographic Printing

by Luminite on Apr 20, 2020 11:03:08 AM

For those of us in the flexographic printing business, we know that changing plates can be a time-consuming process and maintenance is often expensive. We wanted to make a product that cut down on preparation time, increased productivity, and decreased waste.

With our patented Load-N-Lok technology, we were able to achieve those things and more! Here is a breakdown of how our air sleeve technology works.

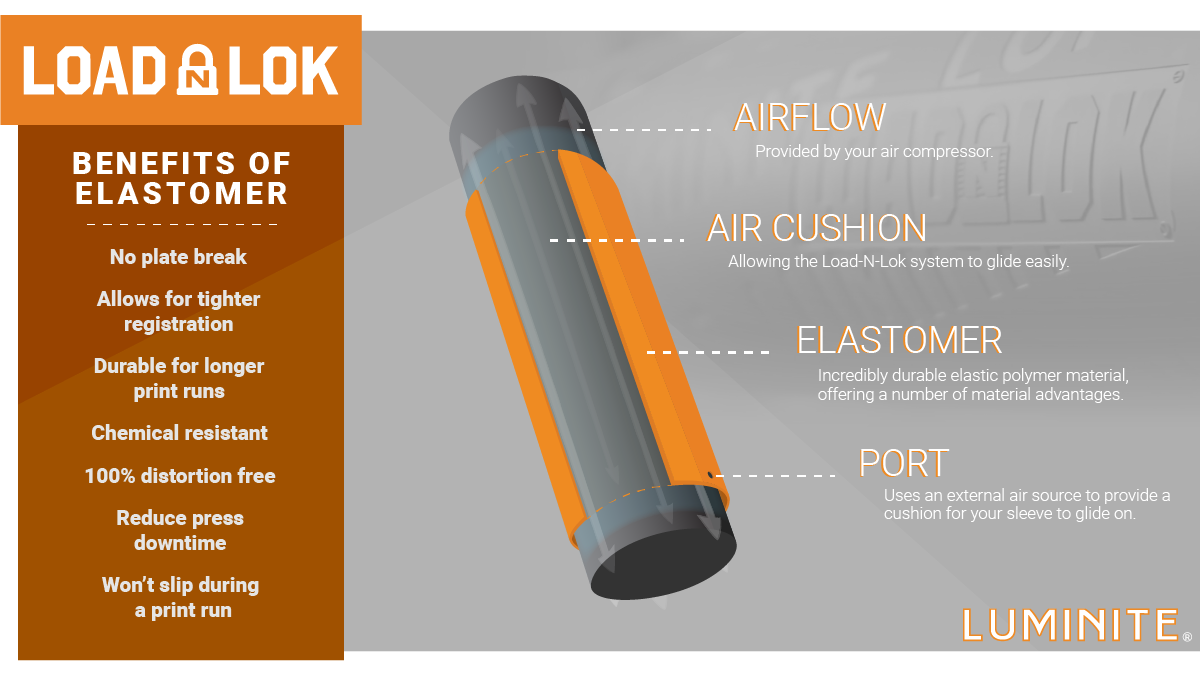

Using Elastomer Sleeve Technology:

Elastomer, an elastic polymer material, is great for flexo printing. Not only is it incredibly durable, elastomer offers a number of advantages specific to the flexographic industry.

Elastomer sleeves, among other things:

- Have no plate break

- Allow for tighter registration

- Durable for longer print runs

- Are chemical resistant

- Are 100% distortion free

- Reduce press downtime

- Do not slip during a print run

The Load-N-Lok technology takes advantage of the benefits of elastomer sleeves by offering an even faster way to get your presses rolling.

Preparing Load-N-Lok Sleeves for Printing

One of the primary features of Load-N-Lok is flexibility. Air lock sleeves can be mounted on multiple different presses if they have the same BCD Mount Base. Load-N-Lok also eliminates the need for an air-assisted mandrel.

Load-n-Lok sleeves that are 2.000” longer than the print width can be mounted on the Mount Base, and you can also mount sleeve lengths as short as 6.000”.

All you have to do to mount Load-N-Lok sleeves is insert an air compressor nozzle into the air feed at the lead sleeve edge to expand the sleeve and push it onto the roller. When the nozzle is removed, the sleeve will lock to the roller and remain stationary.

Load-N-Lok in a Nutshell

If you’re running a long or continuous print, Load-N-Lok air sleeves offer a durable and quick option for flexographic printing.

Photopolymer plates are relatively cost efficient and can be manufactured in house, but are not ideal for longer print runs. They create a lot of waste and often affect the image after a certain amount of time.

By pairing elastomer sleeves with Load-N-Lok technology, we were able to create a fast, easy way to set up your presses without the waste or the frustration of other in-the-round printing methods.

If you’re interested in learning more about how Load-N-Lok can improve your print processes, utilize the button below to get in touch with a member of our team today.

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (4)