Share this

Gear Marks: The Flexo Printing Defect You Can Hear (Sometimes)

by Luminite on Jan 7, 2022 11:04:00 AM

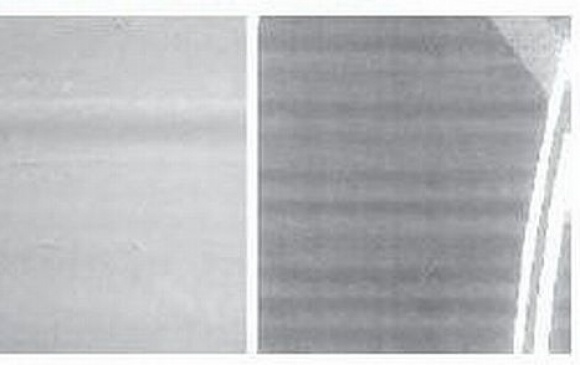

They’re so easy to spot. Gear marks in flexographic printing appear as alternating linear areas of light and dark running perpendicular to the web direction on your press. These nearly always occur in regular intervals across the substrate.

Gear marks are also commonly called chatter or banding. What causes them? More importantly, what do you do about them?

Among the 12 common flexo printing defects we frequently encounter, gear marks have the fewest probable main causes: press mechanics and pressure. But within those 2 causes there are multiple other potential issues making your prints look terrible. The good news is in severe cases you can actually hear off-kilter press mechanics during the printing process.

Let’s get to work.

Identifying and Solving Gear Marks in Flexographic Printing

You’ve likely got the identifying part figured out. The unnatural striations in your images are especially visible in screens and vignettes.

Many other flexo printing defects require fixes ranging from altering ink transferability characteristics to routine maintenance of sleeves, cylinders, and plates. Unfortunately with gear marks, however, the likely culprit is aging or damaged press mechanics. And that, in some instances, could require maintenance and replacement of parts to keep your press in working order.

(The above image is a preview from our larger, complimentary Printing Defects PDF guide that explores many printing defects, including gear marks.)

(The above image is a preview from our larger, complimentary Printing Defects PDF guide that explores many printing defects, including gear marks.)

Worn Gears

The worst cases of gear problems can be clearly audible. Pay attention to gear wear over time.

In almost all cases, worn gears will cause the stripes of light and dark to occur in regular intervals within your printed image. Keep in mind, though, that even if gears are worn or damaged the gear marks will not always correspond to the exact location of a damaged tooth, but rather to uneven bouncing from imbalance.

Drive gears must be cleaned and lubricated regularly to allow gear teeth to meet and mesh in a perfect fit. Poor lubrication could cause gears to grind and cause that bouncing. Over time, gear teeth will wear down, or sharpen, increasing the empty space between them. This, in turn, will cause gear backlash vibration, which also contributes to bouncing on the press.

Pressure Tolerances Between Elastomer & Photopolymer

Typically, traditional photopolymer users are used to printing with greater impression than is appropriate for in-the-round (ITR) elastomer sleeves or cylinders. Due to the precision grinding and high strength of elastomer, a kiss impression is all that’s required for a quality print.

Mismatched Gears

Does your gear have the correct number of teeth for the print repeat required? Are they the right pitch and tooth angle?

For a quality print to occur, the sleeve/plate cylinder, anilox, and impression cylinder must rotate in sync. Mismatched gears will force a related mismatch in speed. This, in turn, causes vibrations on the press and can result in an uneven impression or too much impression at regular intervals appearing as gear marks.

Flexo Printing Defects: Gear Marks Have Many Causes Stemming from Pressure and Press Mechanics

Routine cleaning and maintenance can help to stave off many flexo printing defects. But if you do experience gear marks in your imagery, at least this time, you might be able to hear why they’re happening.

If you have any questions or would like a second opinion, we’re always here to offer troubleshooting solutions. Call (888) 545-2270 to speak with a Luminite customer service representative. The free guide below offers a more comprehensive view on printing problems.

Editor's Note: This blog post was originally published March 9, 2018 and was updated on September 30, 2019 to reflect new insight and resources.

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (2)