Share this

At-a-Glance: Control Technique Guidelines for Flexible Package Printing

by Luminite on May 12, 2020 1:23:34 PM

Flexible packaging is everywhere, from snack wrappers to health products. Flexible packaging printers need to streamline their processes to maximize output, but they also have to maintain environmental standards for volatile organic compound (VOC) emissions.

Here we’ll take a look at some of the guidelines and best practices for production line efficiency and environmental awareness.

How Does Flexible Packaging Printing Work?

Flexible packaging printing encompasses a number of processes in the manufacturing chain. Printing is only a small part of the entire manufacturing process; lamination, cutting and folding are more time consuming than printing.

But, for the sake of this article, we’ll only address the printing aspect of the manufacturing process. There are two primary methods for flexible packaging printing, flexography and rotogravure.

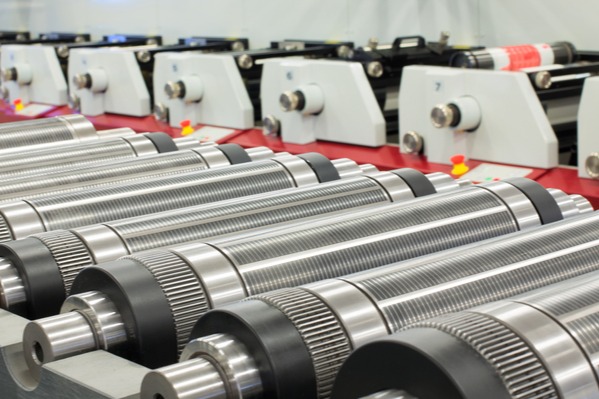

Rotogravure

Rotogravure, commonly referred to as gravure printing, starts with an image or text engraved on a metal cylinder. Very fluid ink is used to transfer the desired image onto the substrate, and some of the ink or coatings and adhesives evaporate as the substrate is passed through hot air dryers. This process releases VOCs, especially if the ink is solvent-based.

Gravure printing is expensive to produce and set up, and is ideal for longer print runs.

Flexography

Instead of using an engraved plate or roller, flexography uses rubber or elastomeric sleeves and plates as image carriers. Flexographic printing uses both water-based or solvent-based inks, but much like gravure printing, there is an amount of VOC off-gassing involved with them.

Flexographic printing is often used for shorter printing runs because the production of plates or sleeves and press set up is easier and faster than gravure set up.

Flexible Packaging Printing VOC Emission Control Methods

There are 2 ways that VOC emissions enter the atmosphere: evaporation from inks, coatings, and adhesives, and evaporation from cleaning materials. To protect the health of your workers and the environment, it is important to implement the correct VOC emission control methods. The most effective ways are described below.

Containment

Capture systems are a critical component of maintaining a VOC-free work environment and limiting emissions. These control systems are designed to capture solvent laden air and push it toward a control device. The system will often include things like

- Fume hoods

- Floor sweeps

- Permanent total enclosures (PTEs)

PTEs are a way to ensure that your workers are kept safe from VOCs, and by enclosing high-risk equipment or areas, you can work toward 100% capture efficiency.

However, PTEs are not always necessary. Many newer flexographic or rotogravure presses have integrated capture systems, often with 85-90% capture efficiency.

Control Devices

There are a number of control devices available to integrate into your warehouse environment to help mitigate VOC emissions.Today, control devices operate with about 95% efficiency in VOC regulation. Most control devices contain

- carbon absorbers

- thermal oxidizers

- catalytic oxidizers

Carbon absorption allows the capture of VOCs as a condensed liquid and promotes reuse or better recycling. Finding out what control device is meant for your workspace depends on the size of your building, the type of inks, coating, and adhesives you use, and how much solvent laden air needs treated.

Low-VOC Inks, Coatings, and Adhesives

While a number of methods have been developed for the capture and recycling of VOCs, there is a way to prevent VOC emission in the first place.

Some flexographic and rotogravure printers use water-based inks, which are more environmentally friendly than other conventional inks. Water-based inks contain alcohols or glycol ethers that help to improve flow characteristics and lower surface tension, and if implemented in printing use, can significantly lower or eliminate VOC emissions.

However, depending on your printing systems, you may need to retrofit your equipment to be able to use water-based inks. Flexographic and gravure printing utilizes hundreds of different inks, coatings, and adhesives, so there is bound to be an eco-friendly available for your printing needs.

Protecting Your Product, Protecting the Environment

Now you know a little bit about the technicalities around VOC emissions, it’s time to think about what else you can do to make your printing processes more efficient.

Flexographic printing is overall more environmentally sustainable than gravure or photopolymer printing. The elastomer sleeves used for flexo last longer than metal plates or cylinders because the elastomer is naturally resistant to most corrosive inks and other materials. By using elastomer sleeves, you can reduce

- Waste from damaged or exhausted rollers

- Production costs

- Time spent setting up complex presses

If you’re interested in how flexo can make your business more environmentally aware and increase your production possibilities, take a look at the services Luminite offers!

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

No Comments Yet

Let us know what you think