Share this

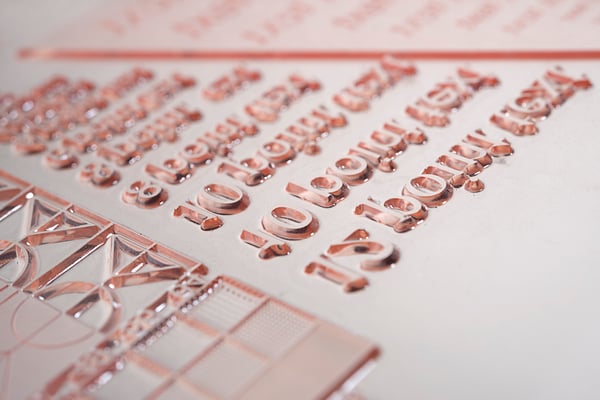

Elastomer Blend Sleeves Eliminate Plate Issues In Flexo Printing

by Luminite on Jul 25, 2021 8:00:00 AM

Looking to stop the excess costs from issues like plate lift, mounting problems, or ink incompatibility when printing? Try an elastomer blend sleeve for your flexographic printing needs.

Blends of elastomer, which can include both natural or synthetic polymers, are used in flexo printing because they are

- High quality

- Long running

- Easier to interchange

- Faster to clean

- Reduce waste

Elastomer sleeves eliminate a variety of problems associated with plates, such as lift, registration issues, and poor ink transfer. They are ideal in applications where a thousandth of an inch is the difference between success and failure.

Better sleeves means better prints, which equals continued sales -- and more revenue.

4 Examples of Elastomer Blends

Here are four examples of elastomer blends -- available in varied durometers and surface tensions -- and their effective flexographic printing uses:

- Natural and natural blends -- for water-based inks. Durometers from 35 to 75 shore A. Surface tensions from 19.6 to 33.9 dynes

- EPDM and EP blends -- for solvent-based and UV inks. Durometers from 40 to 90 shore A. Surface tensions from 20 to 34.9 dynes

- Nitrile and nitrile blends -- for oil based inks and abrasive substrates. Durometers from 50 to 90 shore A. Surface tensions from 25.1 to 33.8 dynes

- Silicone and silicone blends -- for high temperature and adhesive applications. Durometers from 67 to 90 shore A. Material as high as 35 shore D are available for light embossing

How Do Elastomer Blends Improve Printing Performance?

Elastomer blends are used to produce products with a variety of enhanced characteristics that are significant in printing. These can include things like:

- Resistance to wear, heat, or chemical action

- Having specific surface tensions and hardnesses

- And more

These characteristics are obtained by careful choice, and mixing of several different components that make up the final composite material. These include:

- Polymers

- Fillers

- Additives

- Curatives

The choice of all of these components, along with precisely controlled vulcanization (heat and pressure treating) determine the final characteristics of the material. These can be selected to produce a sleeve with various features such as highest quality imaging, unmatched longevity, and superior ink transfer.

Laser engraving of elastomer printing plates and cylinders has been a popular industry practice since it was first introduced to the United States, by Luminite Products in the 1970s. At the time, the quality and longevity of elastomer sleeves made them an attractive alternative to plates mounted directly on cylinders, which were inconvenient to change out and often short-lived

Advances in both elastomer and laser technology have since kept laser-engraved image carriers at the forefront of quality and efficiency in printing.

Elastomer blend flexo print sleeves:

- Enhance both efficiency and productivity

- Can be run alone or in combination with other types of plates

- Reduce press downtime.

When combined with air assist mounting sleeves they allow for almost continuous press operation for maximum ongoing profitability.

Reducing Your Footprint With Elastomer Blend Sleeves

We've talked about the technical side of elastomer blend sleeves and how they can improve both your print quality and your efficiency, but another benefit just as important is their environmental-friendliness.

Elastomer sleeves, are two to three times more durable than photopolymer plates, and often exhibit a resistance to harsh chemicals. This means by using one elastomer sleeve, you're effectively reducing the waste from three photopolymer plates. That's a big difference.

Plus, elastomer blend sleeves are easier to store and care for, and do not require the use of as many harmful chemicals as other flexo printing methods.

Elastomer Blend Product Options

When it comes to sleeves, cylinders, and plates, material choices directly impact the quality of your flexographic print jobs.

Elastomer blends allow you a wide array of options for your printing needs, including:

- Abrasion resistant materials

- Heat resistant materials

- Wide range of durometers

- Wide range of surface tensions

- Multiple repeats on the same base

- Compatibility with all inks

- Optimum transfer of any ink

- And more

Are you experiencing printing defects or having problems with your presses? Maybe it's more than just your image carrier. Check out our free guide to diagnosing your printing problems!

Editor's Note: This article was originally published in May 2017 and has recently been updated.

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (2)