Share this

Mottled Print: Understanding This Common Flexo Printing Defect

by Luminite on Jan 24, 2022 7:30:00 AM

Package printing often requires a great deal of solid-color imagery, even in the most intricate of design patterns.

That black backdrop behind a picture of a product? Solid image. That large, single-color logo affixed to the side of a cardboard box? Yup, essentially a solid image.

As you’re printing these singular color schemes, you’ll encounter mottled print. Among the 12 most common defects we recognize, it’s one of six often attributed to issues with ink transfer. And true to form with many of these defects, there can actually be other causes of mottled image in flexo printing due to a variety of factors:

- Ink viscosity

- Print sleeve/cylinder/plate maintenance

- Irregular substrate surface

- Pressure

- Ink drying speed

- Surface tension

- Anilox condition

Let’s troubleshoot these issues to truly understand common flexo printing defects like mottling and get back to producing repeatable, high-quality prints.

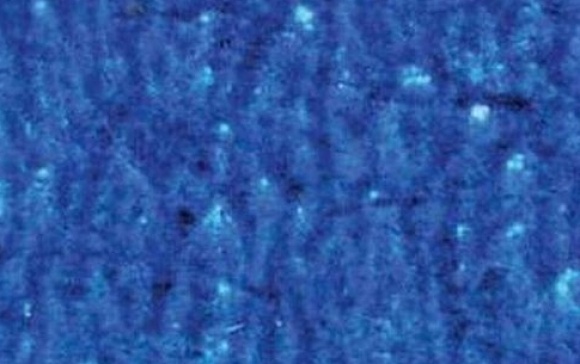

What Does Mottled Print Look Like?

Your substrate comes off the press, and the solid color areas have a noticeable unevenness in print density with minor-to-moderate shade or hue variations. Mottled images can appear bumpy and have the visual consistency of an orange peel.

Ink transfer is the usual suspect. Examine that first.

Ink Transfer Issues

Ink transfer is the basis of all successful flexographic printing. It's the amount of ink being moved through the components of the printing process and ultimately onto the substrate.

In flexo, ink transfer is primarily controlled by three factors:

- Anilox

- Image carrier (cylinder, sleeve, or plate)

- Substrate

Ink must wet out fully on the substrate for a quality print to occur. But even before that can happen, a correct amount of ink must first be transferred from the anilox to the image carrier.

The amount of ink the anilox first transfers to the printing form is determined by the anilox’s cell volume and line count. In essence, less volume/fewer cells equal less space available in the anilox for ink to be picked up and transferred to the printing form or image carrier. Less ink means it’ll ultimately build up less of a uniform coverage on the substrate. Too much ink can cause streaking and running on the substrate.

Choose an anilox with an optimal cell volume/cell count for the printing job at hand. If too little ink is transferring, consider a higher cell volume/lower cell count anilox. If too much ink is transferring, consider a lower cell volume/higher cell count anilox.

As part of routine maintenance, check the cleanliness and physical condition of the anilox roller and clean or replace it, if necessary. Anilox cells often become dirty with dried ink or other contaminants, which reduces the volume the anilox is capable of carrying. If dirty, it needs a thorough cleaning.

Surface Tension

A substrate with a surface tension lower than your ink could cause a mottled appearance. Surface tension refers to the substrate’s ability to pull the ink from the image carrier. A proper surface tension chain (ink, image carrier, and substrate) facilitates adequate ink transfer.

Ink Viscosity

Ink Viscosity

Managing ink viscosity can be a difficult balance. Think of viscosity in terms of how long it would take for a liquid to pour out of a cup. If it pours out like water, it has a low viscosity. If it comes out with the consistency of ketchup, it has a high viscosity.

Your ink has to have the ideal viscosity for the printing job. You can modify the physical characteristics of your ink, following guidelines from your ink supplier.

Under Pressure

Pressure causes more flexo printing defects than any other variable in the press room. Most cases involve skewed images from too much pressure, excessive dot gain, or pushing ink beyond intended printed areas.

In the case of mottled image, however, too little pressure between the print cylinder and substrate causes not enough ink to transfer fully. The result will be a solid color that appears lighter than intended, uneven, or incomplete.

Damaged or Dirty Substrate

It’s nearly impossible to achieve full wet out on a damaged or dirty substrate surface. If your substrate is damaged or polluted, it will almost certainly affect ink transfer. As a solution, you must find the source of the damage or contamination and address it appropriately.

How to Fix Print Mottle & Other Flexo Printing Defects

Orange you glad we’ve discussed how to fix mottle image? All joking aside, this flexo printing defect can come out looking like an orange, but it’s anything but sweet. It can cost you time and wasted substrate if it’s not addressed promptly.

While it likely stems from an issue with ink transfer, viscosity, pressure, or substrate irregularity, it may also be a product of chemicals used to treat the plate or substrate. Even ink drying speed could cause it.

Let’s find solutions. If you experience mottled image or any of these 11 other common flexographic printing defects, don’t hesitate to get a second opinion for troubleshooting solutions. Call (888) 545-2270.

The free guide below explains mottling images and other flexo print quality issues in further detail:

(Editor's note: This article was originally published in April 2018 and was recently updated.)

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (2)