Share this

Defining Wide Web Flexo Printing

by Luminite on Mar 15, 2021 7:15:00 AM

When it comes to package printing, there are three types of flexo printing:

- Narrow web

- Mid web

- Wide web

While all have their share of pros and cons, in this post we're going to focus specifically on wide web printing and the variables that help printers achieve the biggest advantage associated with the technology: speed.

Here's a closer look at just what wide web printing is, what inks are ideal for it, and how wide web differs from mid and narrow web printing.

Wide Web Flexo Printing Explained

As the name implies, any type of wide web printing involves printing on a large substrate. In fact, most wide web printing consists of printing on a substrate that's at least 40 inches wide - a big difference from narrow and mid-web printing.

Due to the size of wide web applications, speed is of the utmost importance. Packaging runs are typically much longer due to the amount of material that needs to be processed. In other words, the speed of wide web printing is arguably its biggest competitive advantage. In order to be viable, it has to be fast.

But how fast your printers can run isn’t the only consideration when it comes to speed with wide web printing. Ink, too, is a prime concern.

Water based inks or UV flexographic inks are popular with wide web printing because they dry faster than conventional oil-based inks.

Finding the right balance for your ink surface tension can also go a long way for increasing the speed of your wide web printing operation.

.

Common Wide Web Flexo Printing Applications

Wide web printing can be used for larger packaging applications, such as garbage bags. However, wide web packaging is often used to process roll flexible packaging that is later cut into smaller end packages, like bags and pouches.

Simple images with only a few colors are fairly easy to print using wide web, but the more complex the image, the worse the quality becomes.

Many brands that are printing simple images in large volumes (think sandwich bags with holiday prints) prefer wide web because it’s far more cost effective than the alternatives.

Wide web is also the preferred method for printing large signs, decals, or stickers. For example, the vinyl floor stickers in grocery stores are all probably made using wide web printing.

Wide Web vs. Narrow Web Flexo Printing

Like we said above, wide web printing tends to be about speed and efficiency. Narrow web printing, conversely, tends to focus more on image quality.

Just how much faster is wide web printing compared to narrow web? A wide web flexo printing machine often operates at speeds at or in excess of 1,000 feet per minute (fpm). Narrow web printing only runs at a few hundred fpm.

The speed at which a printing machine operates at has a direct impact on how the ink is distributed and how it cures. Narrow web printing tends to result in ink that dries more slowly compared to wide web printing, where ink dries faster.

Pairing Speed and Superior Print Quality

Say you want the benefits of wide web printing but you also want to milk a bit more image quality out of the process. Well, by combining the speed of wide web printing with the precision of elastomer printing sleeves, you can.

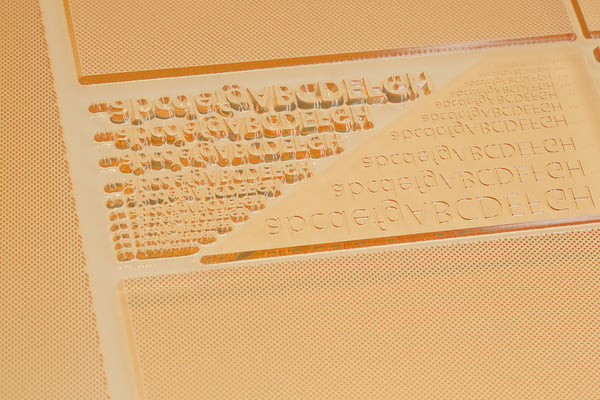

Elastomer printing sleeves or elastomer-covered cylinders are laser engraved to obtain the highest quality etch, which translates to a higher quality print.

Plus, installing elastomer printing equipment is fast and easy, so you can reduce setup time and get your presses rolling. Not to mention using elastomer sleeves reduces overall waste, from production to cleaning.

Flexographic printing is great for wide web printing, but if you want to learn more about the benefits of flexo and elastomer printing equipment, check out our comprehensive guide!

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (1)