Share this

What's the Key to Better Ink Surface Tension & Ink Bonding?

by Luminite on Dec 7, 2021 9:15:00 AM

If you’re in the flexographic printing industry, you know better than anyone that in order to get the perfect print there are hundreds of moving parts to align, test, and measure.

These considerations are only increasing with the development of new technologies and tighter printing requirements -- making the quest for the ideal print seem nearly impossible at times.

But, one facet of flexo has been around since the start of the process, and that's ink surface tension. Testing your surface tension is no small feat, but it can eliminate potentially costly defects while also improving your prints.

Improving Ink Surface Tension & Ink Bonding

Oftentimes, when print after print is coming out defective due to poor ink adhesion (or ink bonding), it’s easy to blame the image carrier. What is too often forgotten is that the image carrier cannot work alone -- its surface energy must fit between the surface tension of your ink and your substrate.

If you’re having problems with your flexo prints and experiencing defects such as:

It might be a result of poor ink surface tension and adhesion.

To avoid ink adhesion-related defects, it's crucial you test the surface tension of your:

- Ink

- Image Carrier

- Substrate

So testing is great, you may be saying, but what's the key to better ink surface tension and adhesion? The devil's in the dynes.

Ink

When printing, you always want your ink to have the lowest dyne levels. It is impossible to give an exact range of dynes for ink due to the variation between ink types -- water-based inks, solvent-based inks, UV inks, oil-based inks, and others all have unique dyne levels.

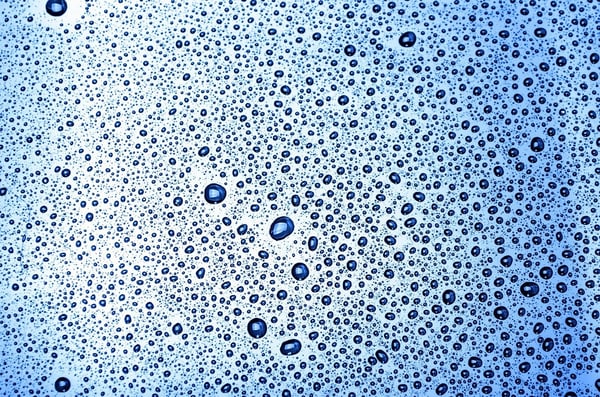

Many press operators mix additives with their ink; such as adding more solvent to counteract humidity, or adding a surfactant to break up the beading in water-based inks. This changes the surface tension of the original ink and can cause defects if the surface tension is not re-tested before print.

Note: If you’re sending ink to your image carrier manufacturer to be tested, it is important to always send press-ready ink that accounts for any additives.

Image Carrier

It is important to always make sure your image carrier surface energy is higher than that of your ink but lower than that of your substrate.

What does a press run look like if you don’t stick to that rule of thumb? If your image carrier surface energy is too high, it will do the opposite of what you’re hoping for and pull the ink away from the substrate. If it is too low, it will not pick the required amount of ink up off the anilox, yielding a defective final print.

Here are some general image carrier surface energy considerations:

- Typically, your surface energy will be between 20-38 dynes.

- Photopolymers one of the lower surface energy’s of image carrier materials, usually clocking in below 30.

- When printing flood-rolls or large areas of solid color, you’re aiming for a dyne level on the higher end of the spectrum.

- When printing fine detail work, you want it to be in the mid-range to lower end of the spectrum.

Substrate

As we mentioned before, you want your substrate to have the highest surface energy in comparison with your ink and image carrier.

Substrate surface energy varies greatly depending on the substrate’s material. Typically, film substrates are treated between 38-45 dynes, though there are some outliers.

Similar to inks, you always want to test your substrate surface energy level before you print. Certain substrate surface energy treatments may degrade if they are left sitting for too long and are not used, especially if proper care and storage are neglected.

The best way to test your surface tension and energy is to send your press-ready samples to a testing facility, which can include image carrier vendors, such as Luminite, that offer the services to their customers. They can also recommend an image carrier that would be ideal for ink adhesion based on the test.

For a quicker method that offers a good estimation, you can run a test on your press. It involves using various test liquids with pre-determined surface tensions to compare with your pre-print surface tensions.

In case you missed it, we have a guide to measuring surface tension with an ink test that explains the different types of inks, how the test works in detail and other important surface tension considerations.

If you tested your surface tension and are still experiencing frustrating flexo print defects, make sure to take a look at our Flexographic Printing Defects Guide:

For more information on flexographic printing or flexo printing defects, check out these blogs:

- Flexo Surface Tension, Surface Energy, and Wettability

- Elastomer Blend vs. Photopolymer Choices in Flexo Printing

- Flexographic Printing Defects: The ‘Doughnuts’ You Can’t Eat

- 10 Common Causes of Print Misregistration in Flexographic Printing

(Editors Note: This blog was originally published in 2020 and was updated in December 2021 to reflect updated and current information)

Share this

- Flexographic Printing (81)

- Image Carrier (28)

- Elastomer sleeves (27)

- Ink Transfer (25)

- Quality (22)

- Flexo sleeve (20)

- News (18)

- printing defects (18)

- flexo printing defects (17)

- sustainability (13)

- Flexo Troubleshooting (12)

- Ink (12)

- Digital Printing (10)

- Flexo 101 (10)

- Flexo Inks, (9)

- Anilox (7)

- Blister Packaging (7)

- Cost (6)

- print misregistration (6)

- regulations (6)

- Corrugated Printing (4)

- pinholing (4)

- "Tradeshow (3)

- Digital Flexo (3)

- Gravure Printing (3)

- Insider (3)

- Load-N-Lok (3)

- Wide Web (3)

- direct laser engraving (3)

- flexo-equipment-accessories (3)

- gear marks (3)

- halo (3)

- testing (3)

- Narrow Web (2)

- bridging (2)

- feathering (2)

- filling in (2)

- mottled image (2)

- pressure (2)

- Labelexpo (1)

- dirty prints (1)

- doughnuts (1)

- embossing (1)

- kiss impression (1)

- October 2023 (2)

- September 2023 (1)

- August 2023 (1)

- July 2023 (3)

- June 2023 (1)

- May 2023 (5)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (3)

- December 2022 (1)

- October 2022 (3)

- September 2022 (2)

- August 2022 (2)

- July 2022 (3)

- May 2022 (1)

- April 2022 (4)

- March 2022 (2)

- February 2022 (5)

- January 2022 (7)

- December 2021 (1)

- November 2021 (3)

- October 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (3)

- June 2021 (1)

- May 2021 (4)

- April 2021 (4)

- March 2021 (4)

- February 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (2)

- September 2020 (1)

- August 2020 (3)

- July 2020 (2)

- June 2020 (3)

- May 2020 (1)

- April 2020 (1)

- November 2019 (3)

- October 2019 (1)

- August 2019 (1)

- July 2019 (1)

- April 2019 (1)

- March 2019 (1)

- January 2019 (1)

- October 2018 (2)

- August 2018 (1)

- July 2018 (1)

- June 2018 (1)

- February 2018 (2)

- October 2017 (1)

- September 2017 (2)

- January 2016 (1)

- February 2015 (1)

- January 2015 (1)

- December 2014 (2)

- September 2014 (1)

- February 2014 (1)

- January 2014 (1)

- December 2013 (3)

- October 2013 (1)

- September 2013 (1)

- June 2013 (1)

- January 2013 (1)

Comments (6)